Metal casting is when molten metal is poured into a mold and allowed to solidify into an object. The object that solidifies is called a casting.

Sand casting is the most widely used metal casting process in manufacturing, and almost all casting metals can be sand cast. Sand casting is pouring molten metal into a sand mold; the metal then solidifies to fill the shape of the mold. A few examples of everyday items manufactured by the sand casting processes are gears, dies used in the packing industry, sports and recreation equipment, cylinder heads, pump housings, and valves.

While proper equipment and experience are required to produce a casting free of defects, the sand casting process itself is pretty simple.

Precision Sand Casting Process in Six Steps

1. Create The Mold

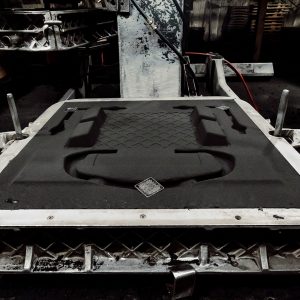

The first step is to create a mold for the sand casting. Form a sand mold by packing sand into each half of a container that includes a pattern of your desired object. The “pattern” is a replica of the external shape of the desired casting. The top and bottom halves of the container mold are known as the “cope” and “drag.” Remove the pattern. The cavity that will form the casting remains. Learn more about the types of sand used in sand casting.

2. Prepare the Mold

Once the mold has is ready, it must be prepared for the molten metal to be poured. The surface of the mold cavity is first lubricated to help with the removal of the casting. The type of lubricant will depend on the kind of sand and metal used. The mold halves are then closed and securely clamped together. The mold halves must remain securely closed to prevent the loss of any material.

3. Pour Molten Metal into Mold Cavity

Pour molten metal into the mold through the “gating system.” A gating system is a gap leading from the casting cavity to the outside of the mold. You can see “jackets” on these molds that secure the two halves together. This image shows pouring molten aluminum into the mold.

4. Allow Metal to Cool

The molten metal that’s poured into the mold will begin to cool and solidify once it enters the cavity, known as the metal solidification process. The mold is open once the proper cooling time has elapsed.

5. Remove Cast from Mold

After the solidification time has passed, break the sand mold apart and remove the hardened casting. A vibrating machine can shake the sand and casting out of the flask. Once removed, the casting will likely have some sand and oxide layers stuck to the surface. Use shot blasting to remove the remaining sand. Recondition sand for reuse.

6. Trim Excess Metal From Casting

During cooling, the material from the channels in the mold solidifies and attaches itself to the casting. This excess material is trimmed from the casting either manually or using a trimming press. The time required to trim the extra material depends on the size of the casting—larger castings require a longer trimming time. The scrap material that results from the trimming is often reused in the sand casting process.

Finish, polish, powder coat

Depending on the intended use of the final product, the casting may be polished or finished to provide a functional or aesthetic surface for its final application. Surface finishes of varying grades can be applied to remove the roughness left on the casting surface.

Ermak can provide raw castings or castings ready for use. Secondary finishing operations, including powder coating, are additional options. Contact Us and with any questions about the casting process.