Metal Solidification is the comprehensive transformation process of a liquid into a solid and the basis of casting technology, including melting, pouring, and re-solidating a metal or metal alloy within a mold to produce a final desired product.

1. Melting

The casting process starts by heating a metal alloy in a crucible until it melts. Heated metal becomes liquid when it reaches its melting point. The melting point of metal depends upon the type of metal or alloy. For instance, zinc alloys melt around 900 degrees F, whereas some of the bronze alloys melt above 2000 degrees F. Pure metals melt at the same constant temperature. Conversely, metal alloys will melt within a range of temperatures depending on the composition of the materials. In its molten state, a metal contains a high amount of energy. The alloy, heated above its melting point, allows enough time for the metal to be poured into the mold before it cools.

2. Degassing & Modification

Before pouring, zinc alloys and aluminum alloys need to be degassed. Degassing is accomplished by inserting a graphite lance into the melt. The lance spins very fast, and then argon or nitrogen is injected through the lance, dispersing it through the melted alloy. The argon or nitrogen moves dissolved hydrogen and other contaminants to the surface of the melt. We then remove this contamination from the surface before we pour the alloy into the mold.

Many alloys require modification before pouring. These modifications increase metal flowability, improve grain structure, remove contaminants, etc. Some of the materials we use to accomplish this are titanium-boron, copper-phosphorous, strontium, manganese, etc.

3. Pouring

After degassing and modification, we test the metal temperature to ensure it is approximately 50-150 degrees Fahrenheit above its desired pouring temperature. The extra 50-150 degrees will allow enough time for the metal to flow throughout the part before solidifying during the pouring process. We transport the crucible or ladle to the pouring lines and pour the liquid metal into readied molds. The hollow cavity of the mold is the shape of the desired end product. Sometimes this cavity is one part, and sometimes, it is several individual parts. It is imperative to keep the crucible lip as close to the sand mold as possible to reduce the velocity of the metal as it enters the mold cavity.

4. Freezing

Once the molten liquid is poured into the mold, it cools rapidly. When the temperature of the liquid metal changes below the melting point of that particular metal or alloy, the solidification process begins. The freezing process usually takes less than a few minutes.

5. Solidification

As the temperature drops further, the molten metal loses energy, and crystals begin to form. This process starts near the mold walls, where it cools first. These crystals eventually become grains within the final structure. If the metal solidifies slowly, the grains are longer. If it cools quickly, the grains are visibly shorter. The crystals (or dendrites) continue to form and harden until the entire melt solidifies.

During the solidification process, the metal is shrinking. Shrinkage occurs because most metals are less dense as a liquid than a solid. Shrinkage can create a void at the last point to solidify. Avoiding shrinkage defects can be accomplished by the use of risers and other techniques. Risers, also known as feeders, are reservoirs built into a metal casting mold that will help prevent cavities in the casting.

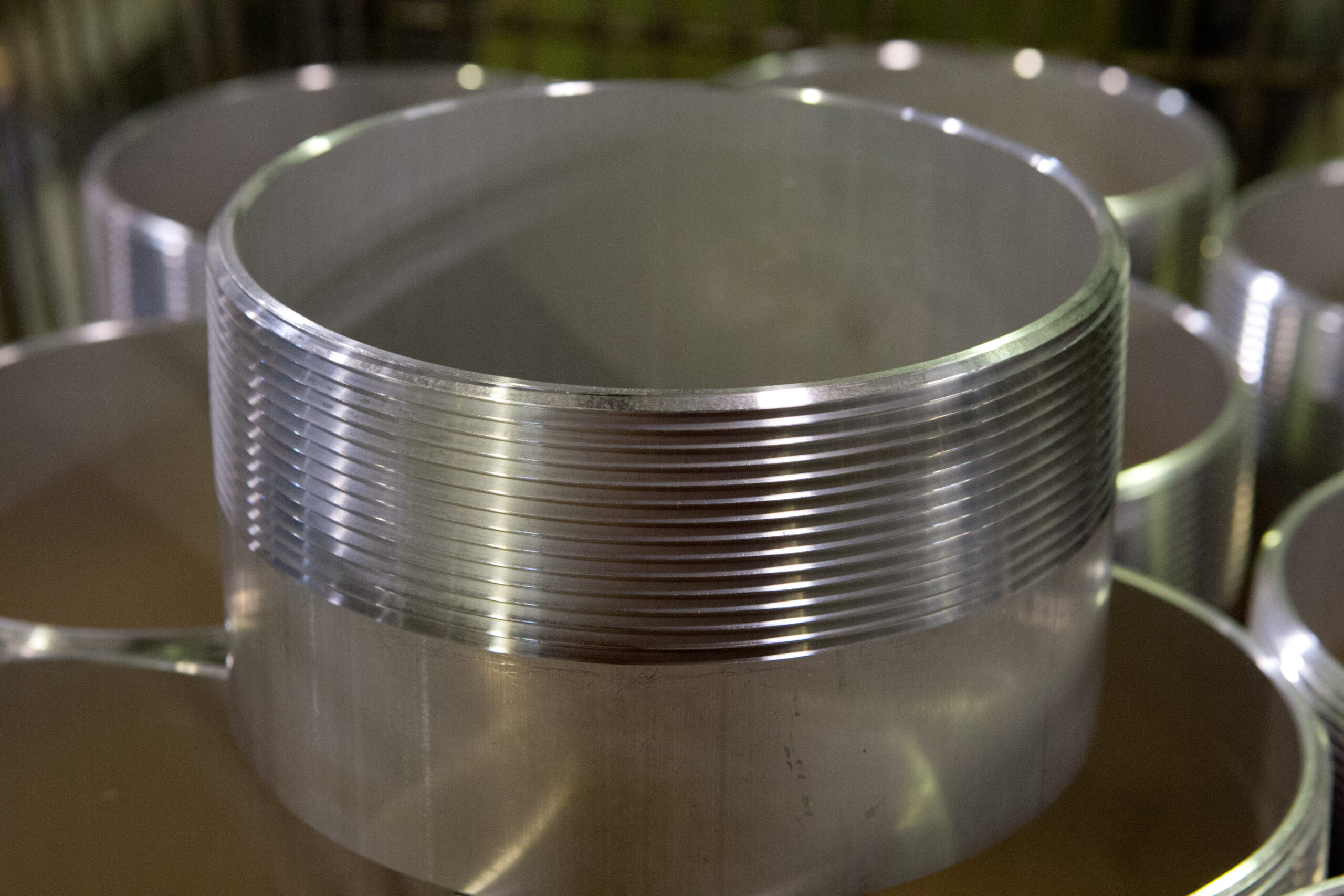

6. Casting

Once hardened, the cooled metal product is removed or shaken loose from the sand mold to complete the solidification process. The finished piece is called a casting.

Although different casting methods employ various equipment and techniques, all observe the metal solidification process. It takes an experienced and skilled foundry to control this process and avoid casting defects that result from improper handling of the solidification process.

Casting Services

Contact Ermak to learn more about our comprehensive non-ferrous foundry services like sand casting, precision casting, aluminum casting, and permanent mold casting.