Heat Treat

Heat Treat

Many aluminum castings are utilized in their “as cast” state. However, some applications require metal properties that are not present in the cast material, such as enhanced strength. In these cases, we turn to the aluminum heat-treatment process.

Ermak’s certified furnaces and controls provide uniform heat transfer to all areas of the castings. In addition, our large high-temperature ovens provide excellent tempering results that are consistent and reliable.

Every day, we heat-treat hundreds of castings and tailor the procedure to our client’s specific needs. This in-house, value-added solution streamlines the process to match the customer’s timetable and budget.

Definitions

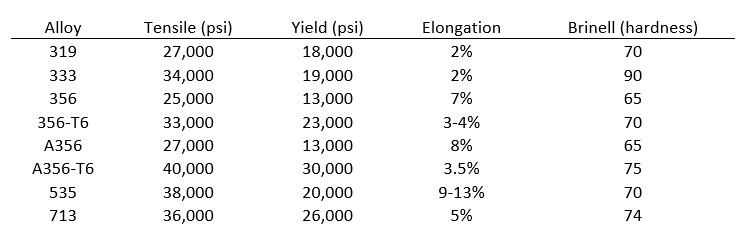

Alloy – A metal created by mixing two or more metallic elements, typically to increase strength or corrosion resistance.”an aluminum, copper, and zinc alloy”

Tensile – The amount of force required to break the material, typically measured in pounds per square inch (PSI).

Yield – The point at which material (under applied pressure) will change its form and not return to its original condition, typically measured in pounds per square inch (PSI).

Elongation – A mechanical property of metal that is the degree to which a material may be bent, stretched, or compressed before it ruptures. It is a point between tensile strength and yield strength and is expressed as a percentage of the original length.

Brinell – A common hardness test done with a round, very hard steel ball which is pressed into the material being tested. The diameter of the mark left in the steel is measured and a table is used to convert this to a Brinell Hardness Number. The higher the number, the harder the steel. Resistance to indentation, scratching, abrasion, or cutting. Materials with little resistance are called soft; those with high resistance are called hard.