By: Reg Zeller

2/4/2026

The Hidden Cost of Cheap Tooling: Why Quality Investment Powers Aluminum Sand Casting Success

Imagine pouring thousands of dollars into molten aluminum, only to watch 35% of your castings end up as scrap due to tooling failures. It’s a nightmare scenario playing out in foundries across the U.S. right now. Especially as aluminum demand surges with reshoring initiatives. And supply decreasing as owners shut down or sell facilities and skilled workers retire. But here’s the good news: investing in high-quality tooling isn’t just a safeguard. It’s a game-changer that can slash scrap rates by up to 50%, boost efficiency, and secure high quality products, on-time. In this post, we’ll dive into why skimping on tooling is costing you more than you think, backed by industry insights and real-world economics. Whether you’re an engineer, procurement manager, or manufacturing exec, understanding this could transform your operations.

The Engineering Reality: Tooling Defines Everything

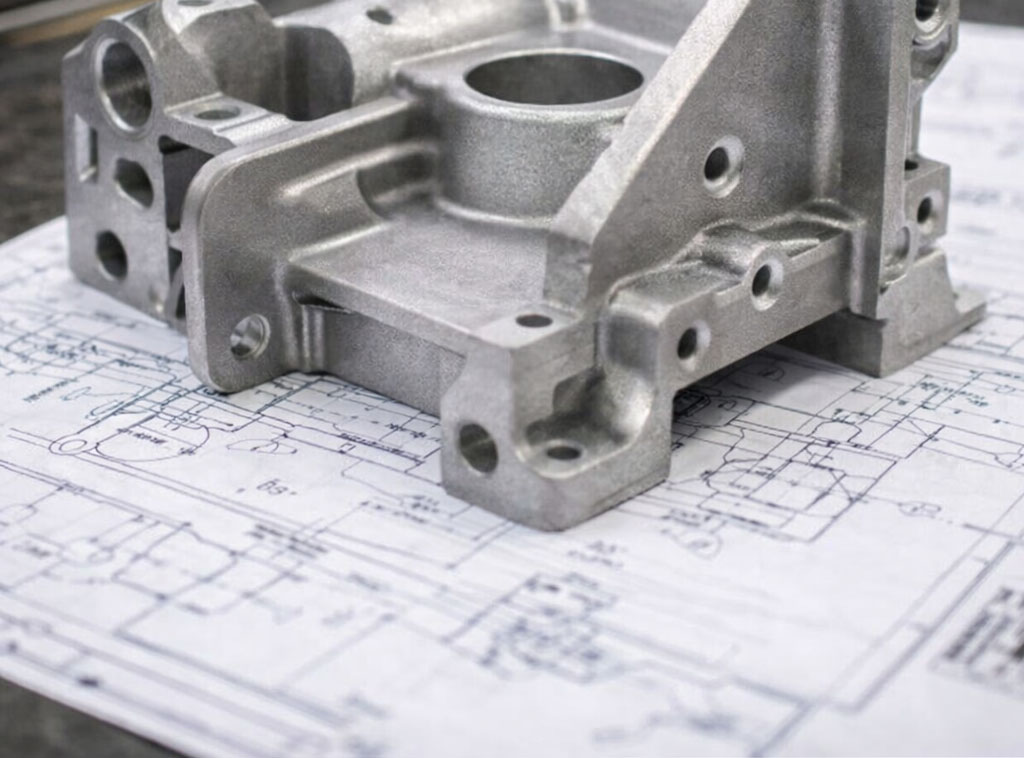

In the world of aluminum sand casting, the pattern isn’t just a blueprint – it’s the foundation of every successful pour. Engineers know this all too well: every critical dimension, surface finish, and draft angle stems directly from the tooling’s precision. What gets poured into the sand is exactly what comes out, we can’t change physics.

At CaneKast, we machine patterns from solid billet or urethane blocks to achieve the precision you need, ensuring your castings hit specs from the first cycle to the thousandth. Why? Because subpar tooling leads to turbulent metal flow, inclusions, porosity, and mold damage. Issues that no amount of rework can fully fix. Recent data from the American Foundry Society highlights that tooling defects contribute to nearly 35% of scrap in sand foundries. A figure that’s even more pressing amid aluminum price volatility, where spot prices have fluctuated up to 20-40% due to global supply chain disruptions and tariffs.

The Hidden Economics of Tooling Decisions

Upfront savings on cheap tooling can feel like a win, but the long-term math tells a different story. For a small foundry producing 1,000 tons of aluminum annually, tooling-related scrap wastes hundreds of thousands of dollars at current alloy and labor prices. Funds better spent on quality upgrades.

Take a real-world example: a customer had a belt guard that required about 1000 castings per year and cost around $50, with quality issues it had climbed to almost $70. The tooling was wearing out and was being produced on an old manual machine. We had welded, re-machined, changed gating, etc for the prior 5 years. This cost the customer thousands in tooling costs and increased part price. Finally, the tool couldn’t be saved, but the customer didn’t have the CapEx for the new tool. Instead, we shared the cost of the new tool and gave a higher piece price until the tooling was paid for, resulting in a $40 piece price and lead time that dropped by a month. The tooling paid for itself inside of a year, and both the customer and us are far happier.

Ready to Upgrade Your Tooling Game?

Don’t let cheap tooling sabotage your success. We’ve seen nearly identical patterns that we create from urethane or billet last 10,000+ cycles when properly designed. Versus less than a thousand for poorly built patterns with inferior materials. Contact CaneKast today for a free consultation. Our experts will assess your applications, recommend precision strategies, and show how we can cut your scrap, enhance profitability, and future-proof your operations. Let’s turn your foundry into a profit engine. Reach out now visit our site to schedule a call.