A common question we’ve received over the years is “I’d like to explore moving my part(s) between foundries but have no idea how to do it.” The simple answer is that as long as there is a detailed process to follow and frequent communication (over communication) between the customer and the foundry transitions are fairly easy. Before we get into the details of how, lets start with some common themes we see.

- A foundry shuts down or is shutting down – the hard reality is foundries have gone out of business domestically (roughly 80% in the last 50 years) due to a number of factors. International competition and retirement are two main reasons, with less people entering the field to continue service to existing customers. We purchased our first two foundries due to retirement, so we are well versed in managing this transition. We continue to look for additional acquisitions across the country as the need for consolidation and scale is paramount to our business.

- A foundry is unresponsive, customer is “too small” or “too large” – sometimes foundries just get too busy, lose or can’t hire enough people (this was especially true pre-COVID), products aren’t a good fit, etc. Hopefully, foundries are transparent when products aren’t a great fit, and will help manage the transition. At Ermak, we are upfront when products don’t fit what we do well and will provide recommendations for other foundries to consider.

- Quality parts and/or on-time delivery become an issue – a lot of different processes in a foundry can cause problems with parts including sub-optimal sand (wrong moisture, improper refresh, incorrect adjuncts, etc.), bad metal (poor raw materials, improper degassing, too much recycling, etc.), incorrect aging/straightening, and a plethora of other issues. These are not easy to manage and require a mix of experience, processes and technology. A dedicated team is essential to identify when some of these issues inevitably occur and ensure they catch the product before it “escapes” from the facility and is delivered to a customer.

- Lack of innovation – the basics of how a part is made in a foundry hasn’t changed substantially in decades (arguably hundreds of years). However, technology is available to automate production, improve processes and measure raw materials that enable firms to be cutting edge. We have invested millions of dollars over the last few years to do exactly that … and this allows customers to get less expensive and higher quality parts, with shorter lead times.

Once a customer has either made the decision to move or is forced to move, there is a detailed process we follow. The high-level overview is below, but rest assured it involves lots of check lists on our side. The process is seamless to a customer besides answering some questions or sending us to work with the other foundry.

The first and most obvious step is to understand the existing product and we go through a series of questions to make sure we get it right. A sample of these questions include but are not limited to:

- Does a customer own the tooling? What is the condition of tooling? What is the part geometry/weight? What are the critical tolerances? What is the annual quantity with any seasonality? What surface finish is needed? What is the first article production lead times required? What is the budget for tooling? What is the pricing needed? Are there any additional needs like finishing, heat treat, paint, etc.? Are there existing issues with the parts?

The process differs slightly when there is existing tooling. This can be an uncomfortable discussion for a customer with another foundry, but this isn’t atypical for foundries to deal with. If customers are not comfortable, we are happy to assist or take care of the process with the existing foundry completely. Typically, we provide budgetary bids with how we would make the part, then modify quotes as needed once we get pictures, actual tooling in our hands, etc.

If new tooling is required because it isn’t owned, is worn out, or the design needs to be updated, we go through our proprietary new product development process. This process includes:

- Process decision – we work with customers to decide what process to use depending on quantity, budgets, tolerances, etc. (green sand, gravity fed die cast/perm mold)

- Design for manufacturability – we analyze the part with the customer to optimize production, minimize cost, ensure quality and lead times.

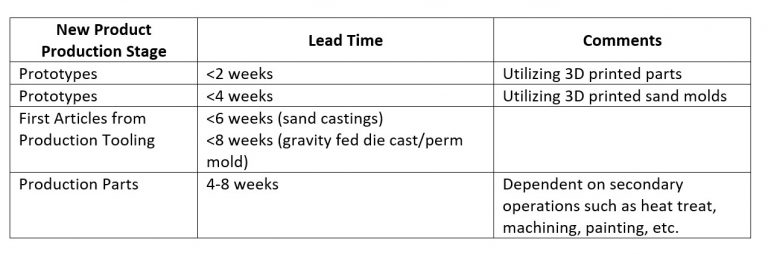

- Procure tooling/provide first articles/start production – Depending on the process used and the complexity of the part, below are typical lead times:

What parts have you moved domestically and what challenges have you faced with switching production facilities? Comment below or to learn more, reach out to our experts at Ermak for free quotes and advice, info@ermak.com or (952) 448-2801.