Pre-COVID, we had been talking with customers who were exploring “reshoring”, the process of moving production back to the US from international manufacturing. The reasons varied, but the most frequent were shorter lead times, lower minimum quantities, higher quality products, concerns over products being copied/sold, more assurances in raw materials used, “Made in USA” for project or marketing purposes, and more access to/communication with the people making their products. Post-COVID and other geopolitical turmoil, those discussions have become much more urgent/frequent as customers experience broken supply chains where they can’t get product, aren’t able to travel to the manufacturing facilities, or a host of other issues.

Leveraging Ermak’s proprietary new product production process, when customers are interested in moving production back to the US, there are a few items we walk through together. First is understanding whether they own the tooling used to make their part, and if so, whether they want to continue making the product using the same process (green sand, gravity-fed die cast/permanent mold, or high pressure die cast). Some of the main aspects include understanding the geometry, weight, tolerances, annual quantity with any seasonality, surface finish needed, lead times required, budget for tooling, pricing needed, any additional finishing (heat treat, paint, etc.), and a host of other items.

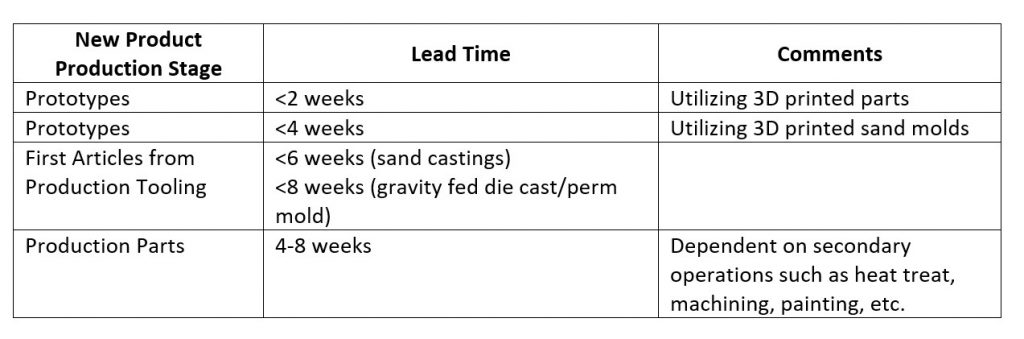

Depending on the process used and the complexity of the part, below are typical lead times:

Most of the time, piece part pricing will be higher in the US than overseas, but we also work with customers to optimize their design for manufacturability so we are able to eliminate costly secondary finishing, reduce weight, improve quality so there are less scrap/warranty costs, etc. Combining those aspects with much lower quantities, shorter lead times, premium market pricing, etc. many customers actually see similar total cost of ownership (TCO) and profitability.

What parts have you on-shored and what challenges have you faced with switching production facilities? To learn more, reach out to our experts at Ermak for free quotes and advice, Info@ermak.com or 952-448-2801.